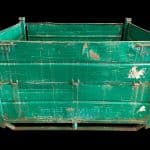

Solid Steel Bins come in various dimensions. They're used to transport manufactured parts from station to station within plants, and also to other facilities for assembly. Some are manufactured with sheet metal sides and floors. These usually have one or two half drop gates, which may be folded down to allow employees easy access to contents.

A second style of solid bins are the steel corrugated bins, which are constructed of corrugated steel. The corrugated steel adds extra strength and durability to these totes. These containers are typically used to carry heavy hot metal parts and the corrugated steel helps prevent the steel bins from warping from the heat. Both types of these solid steel bins may vary in their holding capacity. Their capacity is determined by the gauge of steel used when fabricating them, and also the content of the floor structure. As with most bins, they are stackable. There is one other style of bin that has two hoops, one each on opposite sides of the bin, that extend above the top rail. These hoops allow for a different type of stacking. This type is referred to as "hairpin stacking" bins.

These solid steel bins are used in various industries to material handle components of many, many products. These components could be used in the automotive industry. For example of some of the various vehicle parts are: screws, nuts, bolts, brake pads, callipers, fuel pumps, spark plugs, spark plug wires, valves, tie rods for steering mechanisms, transmission parts, pistons, various lightening apparatus, steering wheels, batteries, wheel rims, radiators, etc…

All these parts are handled in the solid steel stackable bins, totes, containers, to streamline and expedite the manufacturing of the automobile. One could name almost any industry and take a visual inspection of different companies and you'll find that they all are operating using a small quantity up to a very, very large number of metal solid industrial totes, bins, containers.

These sheet metal sided bins, totes, containers are usually fabricated and designed with a hollow structural tubing frame. This consists of four upright posts connected to the framed floor which most likely is constructed with cross members to add strength and durability. These components are welded and secured into a structure. The sheet metal is welded in place to the frame. Some metal bins, totes, containers will have strips of flat bars joining the bottom of the corner posts, leaving gaps between the floor and the flat bar. The positioning of the flat bar produce what are called runners. There may be runners on two opposite sides or may be on all four sides. These runners allow the fork lift driver to insert the forks of the tow motor into the runners of two opposite sides. When the forks are in position the forks are lifted and move metal solid bins, totes, containers.

The runners prevent the solid steel bins, totes, containers, from falling off the forks when travelling on bumpy terrain. Also, these runners allow the fork lift to rotate the metal solid bins, totes, containers so that the bins, totes, containers, have been positioned upside down. This enables the contents of the metal industrial totes, bins, containers to empty at a desired station in the factory for more processing. The content in these bins, totes, containers, may be scraps from production and they are then dumped into the larger scrap metal rolloff boxes and or lugger boxes. These rolloff boxes and or lugger boxes are then picked up by heavy duty trucks and then transported to different facilities where the scraps are either recycled or disposed of in landfill, depending on their consistency.